| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : Altrasonic

Model Number : HSCF20

Certification : CE

Place of Origin : China

MOQ : 1

Price : USD$5000-$30000

Payment Terms : Western Union, T/T

Supply Ability : 100pcs per month

Delivery Time : 15-25 workdays

Packaging Details : Inner case pack, then put in a shipping carton

Material : Food grade titanium

Power : 800W

Length of blade : 305/255/155mm/80mm or Customized

Voltage : 110V/220V

Weight : 10-15kg

Cable length : or Customized

Generator : Digital, auto -tuning

PLC control : Support

Install tape : Hand-held or Mounted on robot

Wattanty : One year

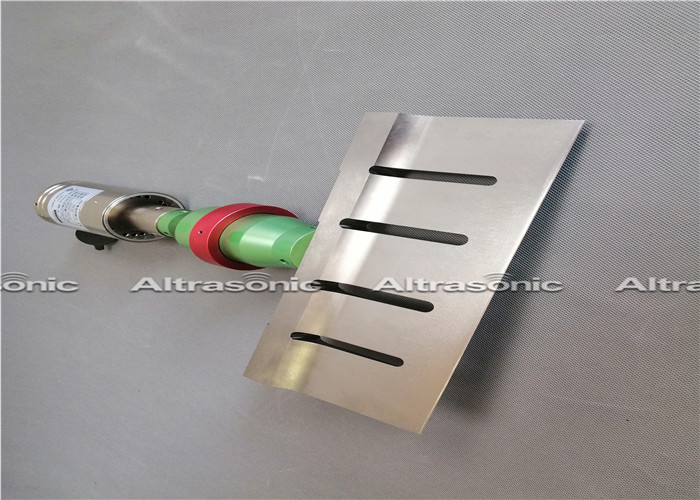

20K Ultrasonic Food Cutter With High-speed Titanium Blade For Cake Slicing

Description:

Ultrasonic cutting ensures a clean cut, with no lost product. Ultrasonic vibrations avoid food sticking to cutting blades, removing the need for cleaning. Foods containing products with different densities, such as cheeses containing nuts, can be cut. Ultrasonic equipment meeting food grade requirements can be totally integrated on production lines, for example to cut slices with constant weight. An ultrasonic cutting head can also be fitted on a robot arm for precise and efficiency cutting.

Specification:

| Frequency | 20Khz |

| Power | 800W |

| Input | AC110-240V, 50/60Hz |

| Power Controller | stepping or continuous |

| Length of the blade | 305/255/155mm/80mm or Customized |

| Material Of Cutting Head | Food grade titanium alloy |

| Machine Wight | 10~15KG |

| Accessories | foot switch, additional blade |

| Cooling Device | compressed air mouth can be installed. |

| Cable Length | or customized |

| Foot Switch | available |

Advantages:

Flexiable to different shapes and patterns

Compatible with soft,sticky and crumbly foods

Safe cuts with less down time

Food grade titanium blade with Self-cleaning function, more sanitary

Zero crumbling and less product loss

• High throughput

• Extremely consistent and reliable performance, virtually maintenance-free.

• Flexible and adaptable equipment with fast set-up and OEM- capable system integration

Applications:

Frozen cakes and pies

·Frozen fish

·Snack and health bars

·Fresh/frozen prepared meats

·Dough or baked cookies

·Soft and hard cheeses

·Fresh/frozen vegetables

·Candy and confections

·Ice cream bars

FAQ:

1. What is the maximum thickness of materials that can be cut?

The maximum cutting thickness is 50mm.

2.What’s the distinct advantages of ultrasonic food cutting machine?

Altrasonic offers a complete line of specialized equipment and components for ultrasonic food cutting. Compared to conventional cutters, ultrasonic food cutters are more sanitary, with less down time, better cost-effectiveness and increased consistency at the cutting surface where the blades stay sharp longer.

3. Can It Be Installed On My Present Lines?

Yes, ultrasonic cutting and processing equipment can be installed easily. Altrasonic equipment can be as simple as removing the conventional knife and replacing it with a plate to which the ultrasonic knives are attached. Another option is replacing the existing cutting/slitting station with a gantry system that straddles the conveyor you now have.

|

|

20K Ultrasonic Food Cutter For Cake Slicing Images |